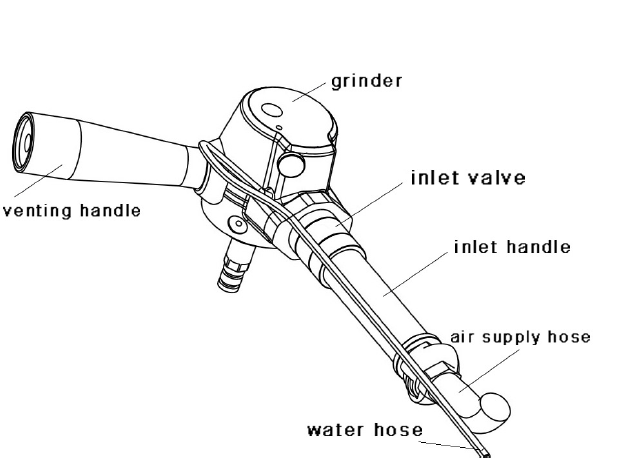

This high-powered grinding head is specially designed for use with our hand-held pneumatic button bit grinder. Its ergonomic throttle and support handle ensure easy, comfortable operation, even in tough conditions.

Simple in design yet built with advanced technology, it offers reliable performance for grinding carbide on button bits—such as DTH and top hammer bits. Compatible with various grinding pins and hex-drive cups, and supports both air and water flush for effective cooling.

Ideal for on-site sharpening to extend bit life and improve drilling efficiency.

Data Sheet | SPD09 |

Air Pressure | 5-7 bar (0.5-0.7Mpa) |

Air Consumption, max | 35L/S, 1.8-2.0m³/min |

Water flushing pressure, max | 4 bar(Psi) |

Ladling speed | 22000r/min |

Air hole diameter | 19mm |

Water hole diameter | 6mm |

For the size of button bits | 6-25mm |

Net Weight | 3KG |

How to use?

1) Open the packing box, take out the grinder and venting handle; screw the venting handle into the air outlet.

2) Air hose connection

A. Connect the air hose came from air compressor to the inlet handle of the grinder (see figure).

The ball valve of the air supply hose from air compressor must be closed, to ensure there is no compressive air in the air supply hose.

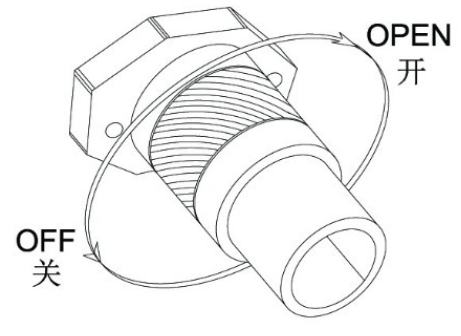

If the air supply hose came from air compressor does not pass through the air filter and oil sprayer, you must connect the air supply hose to the air filter and oil sprayer. And then connect with the air inlet handle from the air filter and oil sprayer. In order to lubricate the rotor and vane, you must check the oil in the oil sprayer and make sure there is enough lubricating oil in the oil sprayer. B. Close the inlet valve on the air inlet shank.

3) Cooling water connection

Attention: the water pressure of cooling water can’t be more than 4 bars.

A. Connect the cooling water hose to the cooling water hose on air inlet shank of grinder by adapter.

B. Tighten the valve on grinder and close the

cooling water hose.

4) Grinding pins assembling

A. Choose correct grinding pin according to the chuck on grinder.

B. Choose correct grinding pin size according to the button size you want to grind.

C. Check the button shape and choose right grinding pins.

D. Check all the “O” rings have been assembled well.

5) Fix the button bit well in right angle. The fixed button bit must be at the best height.

6) Inspection before grinding

A. Check the grease fitting on the grinder and water hose adapter.

B. Check the air hose and water hose connection on the air inlet handle.

C. Check the snap spring on venting handle is solid.

7) Cooling water supplying.

Open the valve, cooling water run out from the center of diamond grinding pin.

Attention: cooling water must be supplied before the aeration to the grinder, or the “O” ring in the grinder will be damaged.

8) Compressive air supplying.

Rotate the valve on inlet handle slowly; the grinder shaft starts to rotate.

Attention: before the aeration to the grinder, take the grinder tightly to keep off dropping.

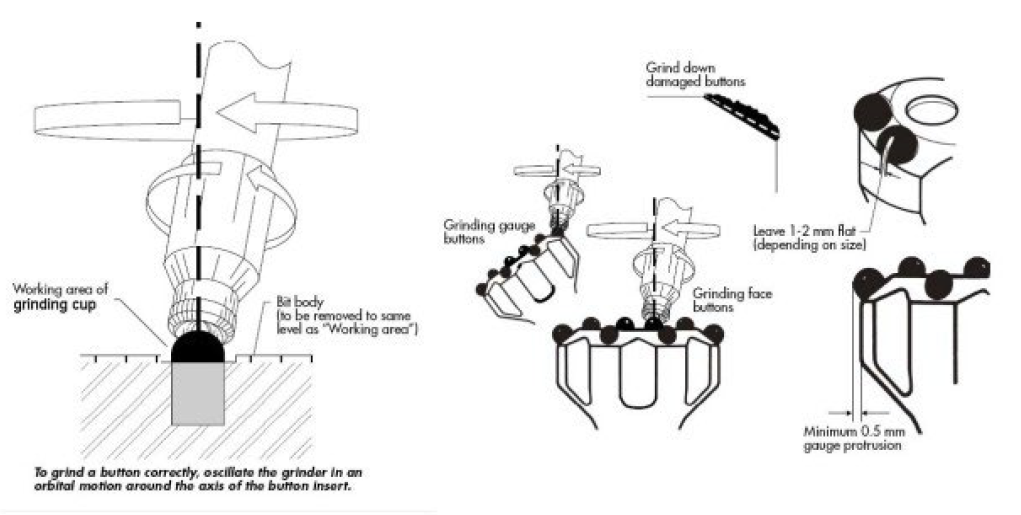

9) Put the grinding pin on the button needed to be grinded, start grinding and adjust

the inlet valve and grinding speed.

Attention: when grinding, make an angle between

the central line of grinder shaft and the central line

of the buttons. In order to make the shape and

angle are same as before.

Remember don’t make the central line of grinder

shaft and the central line of the buttons on the same line, to keep off sharp point of the top of button caused from the cooling water bath on the grinding cup.

After finish grinding one button, adjust the angle of bit and grind the other till all buttons are grinded.

10) When you want to stop grind, close the air valve first, then close the cooling water.

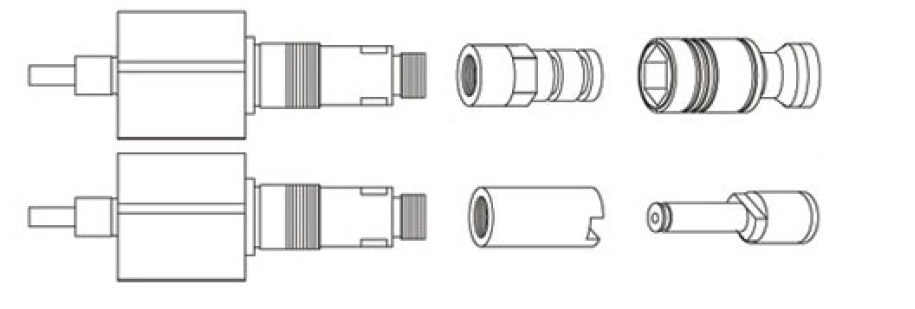

The machine can quickly connect to Different Grinding Cup Types:

Thanks to its interchangeable quick chuck system, this button bit grinding machine offers exceptional versatility—allowing operators to effortlessly switch between different types of grinding cups (also known as grinding pins), including:

a. WING drive cups with 8mm shank

b. SVK's high-performance SAN-drive cups with 9mm shank

c. Atlas Copco's industry-standard 55-drive cups

d. CME’s reliable hex-drive grinding cups

Contact: sales@superdrill.com.cn

Phone: 86-18186993613

Tel: 86-18186993613

Company: Hubei Superdrill Mechanical Equipment Co.,Ltd

Add: Building 3, Rainbow road,No.188 ; wuhan ;Hubei province