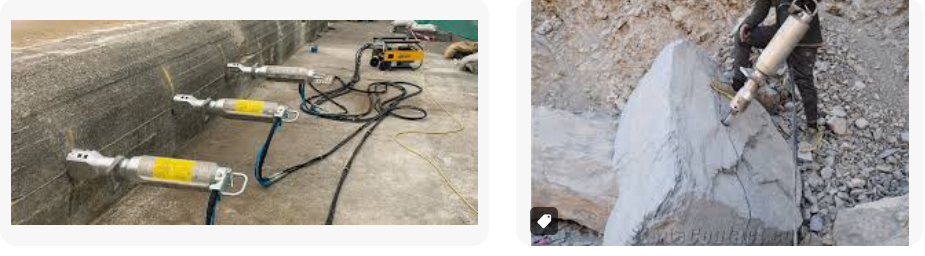

Breaking rock without explosives is no longer a challenge. With the right hydraulic rock splitter, you can safely and efficiently split rocks or concrete — even in urban areas or sensitive sites.

In this guide, we’ll introduce the 3 best hydraulic rock splitters for sale in 2024, explain how they work, and help you choose the right one for your project.

According to recent industry data, global demand for non-explosive rock breaking equipment is growing by 6% annually, especially in mining, construction, and urban demolition sectors.

Hydraulic rock splitters offer:

✅ No explosives required

✅ Minimal noise, vibration, and dust

✅ Safe for use near buildings and infrastructure

✅ Efficient for hard rock, concrete, and boulders

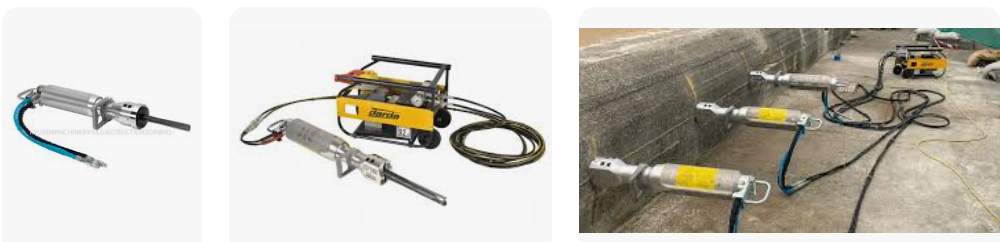

The classic German-made splitter for precision work.

Key Specs:

✔ Splitting Force: Up to 413 tons

✔ Drill Hole Diameter: 45–48mm

✔ Weight: ~32kg

✔ Application: Quarrying, block splitting, controlled demolition

Why Choose:

✅ Lightweight & portable

✅ Ideal for confined spaces

✅ High splitting force for its size

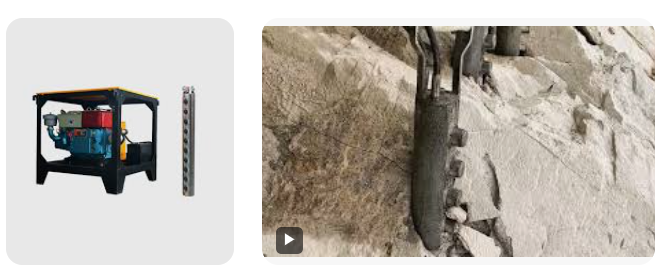

Heavy-duty option for large rocks and concrete.

Key Specs:

✔ Splitting Force: 500–1500 tons (model dependent)

✔ Drill Hole Diameter: 90–150mm

✔ Application: Tunnel excavation, foundation removal, large rock breaking

Why Choose:

✅ Extreme splitting force

✅ Suitable for large-scale projects

✅ Compatible with handheld or excavator-mounted operation

A reliable, affordable option for quarrying and demolition.

Key Specs:

✔ Custom splitting force available

✔ Drill Hole Diameter: 50–150mm (options)

✔ Application: Mining, road works, concrete removal

Why Choose:

✅ Competitive factory-direct price

✅ Fast delivery worldwide

✅ Technical support & spare parts

Contact: sales@superdrill.com.cn

Phone: 86-18186993613

Tel: 86-18186993613

Company: Hubei Superdrill Mechanical Equipment Co.,Ltd

Add: Building 3, Rainbow road,No.188 ; wuhan ;Hubei province