Hydraulic piston-powered rock splitter

Piston rock splitter is a new type of rock-breaking equipment. Its design is inspired by our common hydraulic jack. Using a piston rock splitter requires a larger hole diameter than a hand-held rock splitter (typically 90mm, 110mm, 130mm, 150mm, 180mm, or over 220mm).

In many large rock- breaking construction sites, such as road construction or building foundation sites, it is difficult for a handheld wedge rock splitter to meet a large number of rock removal requirements. So using a piston rock splitter is the best way.

Piston rock splitters are more powerful and efficient than handheld wedge rock splitters. It is fully capable of all kinds of large-scale rock-breaking work.

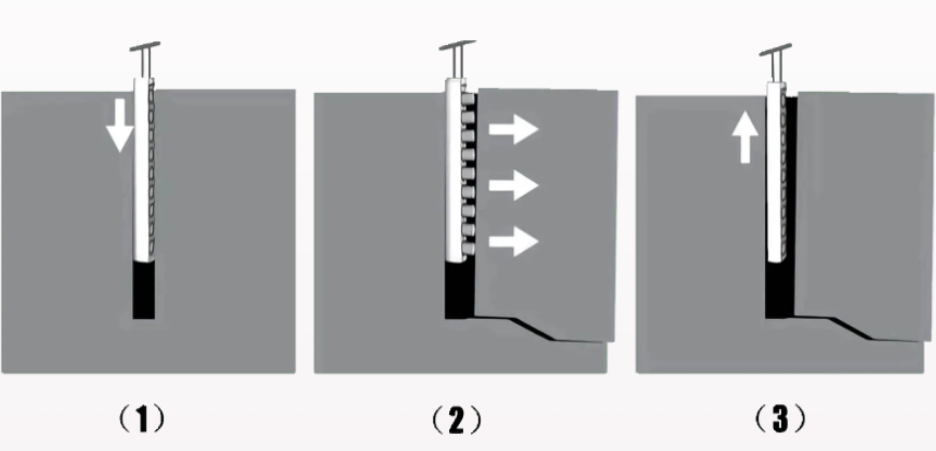

First, drill a hole with the right depth and diameter. Then put the piston splitting rod into the hole and set the direction you want to split. The hydraulic power unit sends high-pressure oil to push the piston, creating a very strong force. The pressure can reach over 100 MPa, producing several thousand tons of splitting force to break the rock from the inside.

PRODUCT DETAILS

Splitter Piston

The piston is made of 40Cr steel, which provides excellent strength and durability to handle the strong splitting force. We also supply easy-to-replace seal kits for the pistons, ensuring convenient maintenance and long service life.

Hydraulic Hoses

We supply the hydraulic hoses together with the oil shunt valve. The hose length can be customized according to the actual working range. Normally, the main hose is 5 meters long, and both the inlet and return hoses are also 5 meters each.

Pump Head

Each hydraulic pump head, whether electric or diesel type, is strictly tested in our workshop to ensure stable and reliable performance during operation.

Splitting Unit

A complete splitting system usually includes 1–6 splitting rods, a pump station (available in diesel or electric options), hydraulic oil hoses (inlet and return), and a shunt valve (1–3, 1–4, 1–5, or 1–6 configuration).

| Model | Drilling Diameter | Drilling Depth | Practical Splitting Force | Unit Weight | Working Pressure | Spacing Distance | Pump Type |

|---|---|---|---|---|---|---|---|

| SPD-90 | 90 mm | >1000 mm | 260 Ton/pc | 32 kg | 120 MPa | 500–700 mm | Electric / Diesel |

| SPD-110 | 110 mm | >1000 mm | 411 Ton/pc | 47 kg | 120–150 MPa | 1000–1500 mm | Electric / Diesel |

| SPD-115 | 115 mm | >1000 mm | 420 Ton/pc | 57 kg | 120–150 MPa | 1000–1500 mm | Electric / Diesel |

| SPD-130 | 130 mm | >1000 mm | 520 Ton/pc | 80 kg | 120–150 MPa | 1000–2000 mm | Electric / Diesel |

| SPD-150 | 150 mm | >1000 mm | 600 Ton/pc | 100 kg | 120–150 MPa | 1200–2500 mm | Electric / Diesel |

| SPD-180 | 180 mm | >1000 mm | 780 Ton/pc | 168 kg | 120–150 MPa | 1200–3000 mm | Electric / Diesel |

| SPD-250 | 250 mm | >1200 mm | 1250 Ton/pc | 330 kg | 120–150 MPa | 1500–5000 mm | Electric / Diesel |

Note: The above data is for reference only. Specifications and configurations may be adjusted without prior notice. Custom designs are available to meet specific project requirements.

| Engine Type | Power | Fuel Tank Capacity | Working Medium | Working Pressure (MPa) | Flow Rate (L/min) | Compatible Splitter Quantity | Dimensions (mm) | Weight (kg) |

|---|---|---|---|---|---|---|---|---|

| Electric Type | 4 KW | 30 L | 46/68 wear-resistant hydraulic oil | 63 | 2–13 | 1–6 | 384 × 280 × 260 | 75 |

| Electric Type | 7.5 KW | 100 L | 46/68 wear-resistant hydraulic oil | 63 | 4–16 | 1–6 | 1150 × 1050 × 980 | 135 |

| Diesel Type | 8 HP | 40 L | 46/68 wear-resistant hydraulic oil | 63 | 2–13 | 1–6 | 1200 × 1170 × 800 | 120 |

| Diesel Type | 18 HP | 100 L | 46/68 wear-resistant hydraulic oil | 63 | 4–16 | 1–6 | 980 × 830 × 1250 | 345 |

Note: The above data is for reference only. Specifications may change without prior notice. Customized pump units are available to meet different project requirements.

FAQ on Hydraulic Piston-Powered Rock Splitter

Q: What type equipment is used for drilling the hole for inserting the splitter rod and what is the general required diameter of the pre-drilled hole?

A: For open pit mining, using a down-the hole tracked drill for drilling is highly efficient. In urban infrastructure construction, a terrazzo drill can be used. For some conditions, customer can also drill the hole with a borehole drilling machine.

Normally hole diameter starts from 90mm-250mm, but we can customize the splitter rod as per customer requirement.

Q: Can you explain the splitting force of your large splitter effect?

A: The piston splitting rod is suitable for large-area rock splitting. It is the latest and most efficient rock-breaking tool currently used to replace explosive charges for mechanized large-scale rock excavation. It consists of an ultra-high-pressure pump station and a piston splitting rod, with a pressure of 150 MPa. When used in combination, the splitting force reaches 7,200 tons per unit (actual splitting force). It requires a drill hole of 250 mm in diameter and 1.1 m in depth. After inserting the hydraulic rock splitting rod, the splitting time is 1 minute, and the splitting depth can reach 1-3 meters.

Q: Do you offer the customization service for the piston splitters?

A: Yes, we can customize splitting rod length, piston numbers, diameter for our customers. Paired with our hydraulic oil station(available in diesel and motor-driven versions), one pump station can support up to 6 splitters. We also offer hydraulic hoses in appropriate lengths to ensure seamless operation, fully meeting your project requirement.

Q: How to choose between the Diesel and Electric Hydraulic Power Pack, which one is more powerful?

A: Due to the lack of electricity access, some customers will choose diesel one for the site works. They are having the same power, normally we suggest to adjust to 120Mpa pressure to work with the piston splitters.

Q: How long is your product warranty period?

A: We offer a one-year comprehensive warranty on the entire machine excluding the wearable parts. Additionally, we offer lifetime technical support to ensure the smooth operation.

Contact: sales@superdrill.com.cn

Phone: 86-18186993613

Tel: 86-18186993613

Company: Hubei Superdrill Mechanical Equipment Co.,Ltd

Add: Building 3, Rainbow road,No.188 ; wuhan ;Hubei province