Buying Taper button bits may seem simple—but making the wrong choice can lead to poor drilling performance, higher costs, and even equipment damage.

In this guide, we’ll highlight 5 common mistakes buyers make when choosing taper button bits—and how to avoid them. Whether you're sourcing for quarrying, mining, or construction, this is the checklist you need before placing your next order.

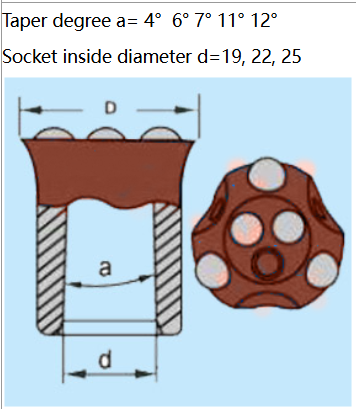

Not all taper angles are universal. Common angles include 7°, 11°, and 12°, each suited to specific rock conditions and drilling setups.

7°: For longer rods, higher torque, and difficult terrain

11°: General-purpose; most widely used

12°: Better for short-hole, high-speed drilling

Tip: Check your drill rod and hammer compatibility before ordering.

The shape of the carbide buttons affects penetration speed, wear resistance, and chip clearance.

Dome-shaped: Longer life, best for hard and abrasive rock

Ballistic shape: Faster penetration, but wears quicker

Parabolic or semi-ballistic: A balanced option

⚠ Choosing the wrong button type can slow down your drilling and shorten bit life.

Not all 32mm or 38mm bits are created equal. Manufacturing tolerance (e.g. +0.5mm or -0.3mm) can affect bit fit, drill rod life, and hole accuracy.

Choose suppliers with strict CNC machining and quality inspection—like SUPERDRILL.

Low-cost bits may save money up front, but poor materials lead to more frequent replacements, slower drilling, and higher total cost.

Invest in heat-treated alloy steel and premium-grade tungsten carbide—you'll drill faster and replace less.

Some buyers order the same bits for all jobs—ignoring rock hardness, abrasiveness, and hole depth.

Granite, quartzite, basalt → Use dome carbide with high wear resistance

Limestone, clay, sandstone → Ballistic or semi-ballistic for speed

Anchor drilling → Smaller diameter and tighter taper fit

The more specific your bit choice, the more efficient your drilling will be.

SUPERDRILL provides customized solutions for your rock type, hammer model, and project requirements:

Taper angles: 7°, 11°, 12°

Diameters: 28–45 mm

Carbide options: Dome, Ballistic, Semi-Ballistic

Compatibility: YT24, Y26, YN27C, and more

Global OEM supply with fast lead time

Contact: sales@superdrill.com.cn

Phone: 86-18186993613

Tel: 86-18186993613

Company: Hubei Superdrill Mechanical Equipment Co.,Ltd

Add: Building 3, Rainbow road,No.188 ; wuhan ;Hubei province