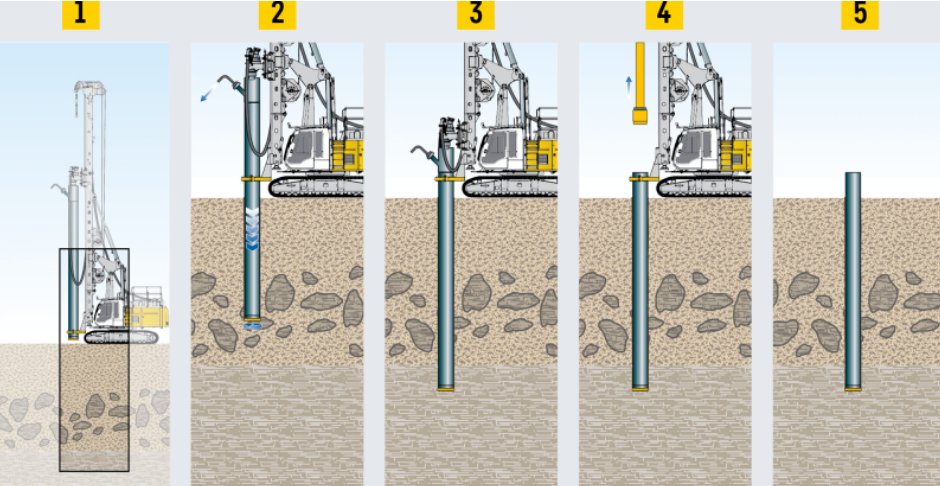

1. Positioning the drill rod and casing on the drilling point using the DTH hammer.

2. The drillstring is drilled rotary and percussion while compressed air is supplied.

3. Using a pilot bit and DTH hammer, unlock the drill rod after you have reached the bottom.

4.Removing the pilot bit, DTH hammer, and drill rod from the casing

5. A fully enclosed borehole.

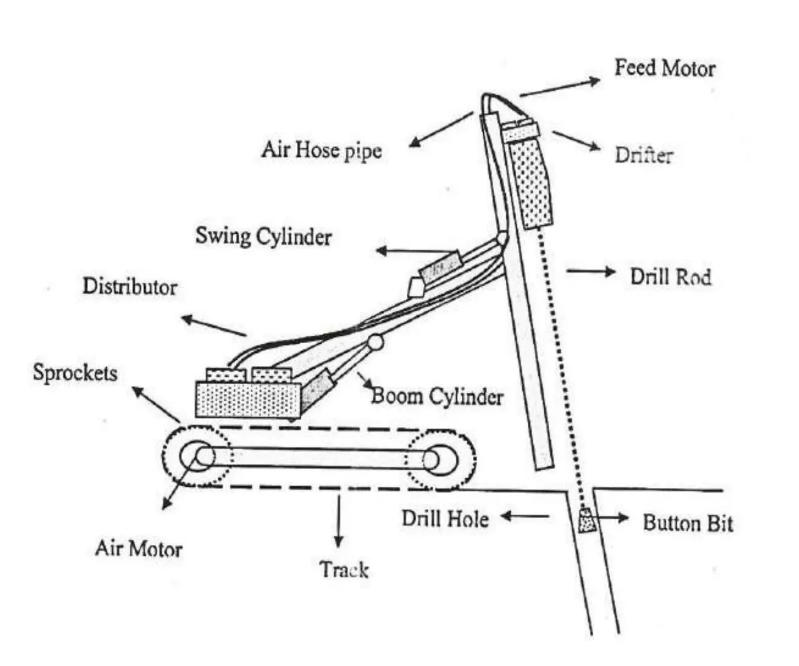

When using top hammer drilling, the drill bit is subjected to a percussion force from the hammer on the drill rods or tubes. The feed device is often mounted to a mobile machine with a hinged boom.

Among rotary percussive methods, top hammer drilling is the most commonly utilized technique.

The oldest method of drilling blast holes is rotary-percussive drilling, which is extensively employed in the mining and civil engineering industries.

Rotating percussion drilling is divided into two categories based on how the two main performances—hammer impact and rod/bit rotary—operate differently:

Top hammer drilling (THD) and down-the-hole (DTH), commonly referred to as in-the-hole (ITH), are the two drilling techniques.

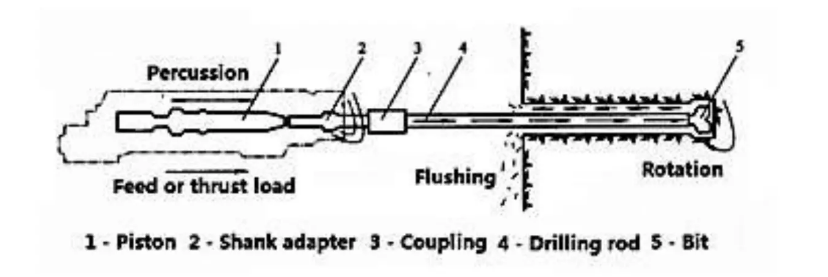

2) Rotation: The rod is rotated by the rotary mechanism. The bit is rotated with this action, producing impacts on the rock in various places.

3) Feed load, also known as thrust load, is necessary to maintain contact between the drill bit and the rock as well as between the shank and the drill. By doing this, the piston and the rock will transfer the maximum amount of impact energy.

4) Flushing: Flushing is used to cool the bit and remove the rock shaving from the drill hole.Through the flushing hole in the rod and the hole in the drill bit, the flushing medium—air, water, mist, or foam—is driven to the bottom of the drillhole.

The striking bar or shank piece that is put into the chuck at the bottom of the drifter receives its energy from the piston.

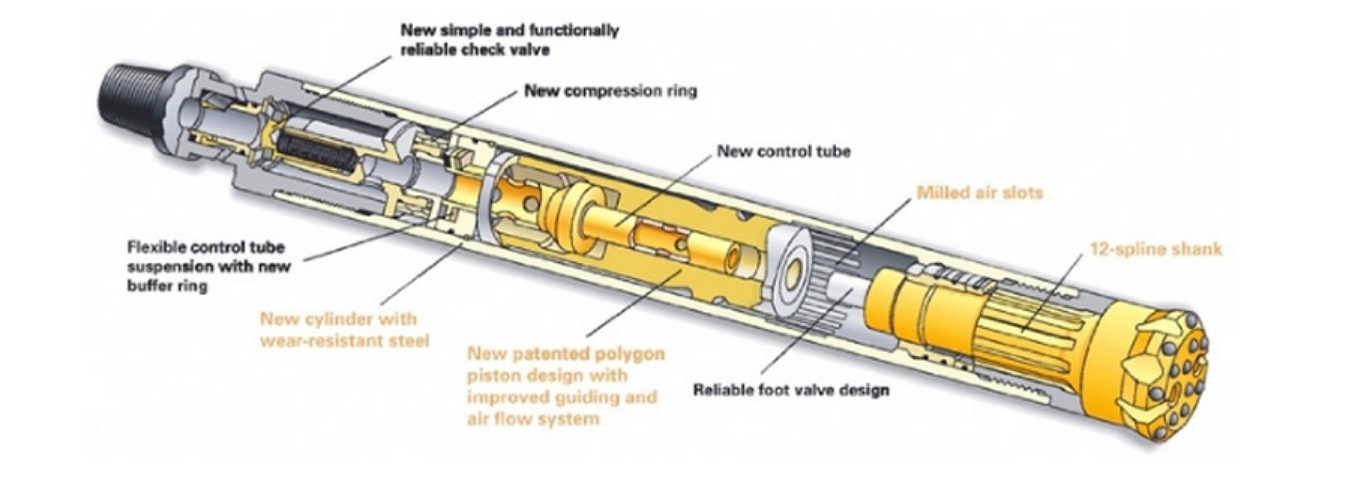

The impact energy in percussive top hammer drilling is produced when the piston strikes the adaptor.

The striking bar or shank piece (adapter) placed in a chuck at the bottom of the drifter receives the energy from the piston.

This shank uses a number of drill "steel" or rods connected by detachable couplings to transfer the blow to the bit.

Contact: sales@superdrill.com.cn

Phone: 86-18186993613

Tel: 86-18186993613

Company: Hubei Superdrill Equipment Co.,Ltd

Add: Building 3, Rainbow road,No.188 ; wuhan ;Hubei province